|

|

|

|

|

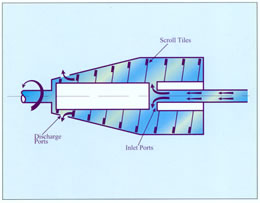

FINE GRAINED REACTION BONDED SILICON CARBIDE

FOR CENTRIFUGE WEAR PARTS

The choice of material for your centrifuge wear parts is a critical one as it will dictate your future maintenance costs and in many ways the operating efficiency of your expensive centrifuge.

OEM's, refurbishers and end users are now taking advantage of Refel's proven 'supreme' wear resistance and low weight.

|

|

REFEL BENEFITS-

- Greater wear resistance than tungsten carbide, reducing replacement costs.

- Lower weight than alumina, reducing start-up torque and power consumption.

- Scroll tiles can be bonded or welded in position.

- More inert to chemical attack than tungsten carbide.

- FDA acceptable.

- Low cost tooling.

- Complex shapes readily produced.

- Rapid design and delivery to suit your centrifuge.

|

|

|

|

Centrifuge Parts Available

Scroll Tiles / Inlet Ports / Discharge Ports / Bushes / Saddles

Other Wear Parts Available in Refel-

|

|

- Cyclone/Hydrocyclone Components

- Blasting Nozzles

- Coal Injection Bends

- Cyclone components

- Hydro cyclone components

- Centrifuge wear tiles

|

|

- Shot blast nozzles

- Spray nozzles

- Fluidised bed dryer components

- Burner nozzles

- Pipe Linings

- Coal Injection Bends

|

|

|