|

|

![]() |

Advantages

FEROLUBE - bearing can be used for applications, where on other kind of lubrication is possible.

FEROLUBE - bearing can be used at temperatures up to 4500c

FEROLUBE - bearing have nearly the same friction- coefficient in all conditions.

FEROLUBE - bearing can be used for applications in fluids, e.g. seawater, because the solid lubricant will not be washed away.

FEROLUBE - lubricant is not inflammable.

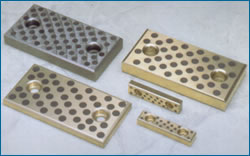

FEROLUBE - is also available as waer-plates, flange-bearings, spherical bearings and other parts according to customers drawings.

Calculation and Design

We recommend the use of our data-sheet to send us your technical details.

|

Bearing load

The specific load in N/mm2 will be calculated by using the projected area (inner diam. x length).

According to the value of this load, the backing material of the bearing will be selected.

Velocity

The sliding velocity has to be calculated in m/s.

|

|

|

Temperature

FEROLUBE - bearing can be used up to temperatures of 4500c

Dimensions

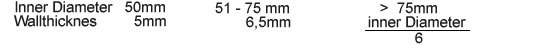

For the tight fit of the lubricant-plugs in the bearing, a minimum wallthickness of 5mm is

required. please pay attention to the following table.

We recommend a bearing lengh of 0,8 - 1,5 x inner diameter.

If there are on other statments, the bearings will be produced for redial movement only.

Friction coeffcient

The value of the friction coeffcient is depending on many disserent factors.For dry running, the desing

should be based on u=0,1. This postulates Ra 0,2 - 0,8 um surface finish of the mating surface. When used

in water or other liquids, the coefficient goes down as 0,03. At higher temperature it will raise up to 0,2.

|

|

|

Mating surfaces

Ganerally the mating surface should have a hardness of min. 100HB above the bearing backing material.

When using high strength Aluminum or Nicket-bronzes as becking material, the mating surface should be

handened. If using FEROLUBE in aggressive atmosphere, stainless steels in heat treated condition should be selected

as mating material.

|

|

Tolerances and clearances

Solid lubricant bearings are designed to be installed in a H7 housing. The shafts must have minus

tolerances as e.g. f7. This takes in account, that the inner daimeter shrinks due to the pressfit during installation.

|

|

The lubricant film, wich is building up on the sliding surfaces, needs clearances wich are larger than under fluid

lubrication. This fact bas been considered with corresponding larger tolerances of the bearing I.D. in delivered state.

The tolerances are for temperatures  800c. 800c.

Housing bore H7

Bearing O.D. r7

Bearing I.D. D10 (I.D. 30-80mm)

Bearing I.D. C8 (I.D. over 80mm)

Shaft f7

For higher temperatures contact TENMAT-WERKE.

Matingmaterials

All kind of steels with min. 100 HB hardness above the bearing material are recommended. For

high strength bearing materials as AI or Mg or Ni bronzes, the mating materials should be heat-

tredted or hardened. When used in humid surrounding,' water or aggressive atmosphere, chromium-

nicket steels should be used.

For best life results, the shaft finish should be 0,8 -1 m Ra. m Ra.

|

| |